When different industrial machines are operated by the operators, it is most likely to get large amounts of resultant dust and waste particles that are formed during the actual production of the end products in those manufacturing units. But many workers are seen to be allergic to these dust that may make them fall sick and as a result, industrial works are hampered. Also, the operational effectiveness of the machines is badly affected by the accumulation of unwanted debris over the movable machinery parts. Hence, the uses of vacuum filters are highly beneficial in keeping the working areas of the factories fully clean and free from all harmful particles.

Information About the Industrial Usage of Vacuum Filters

|

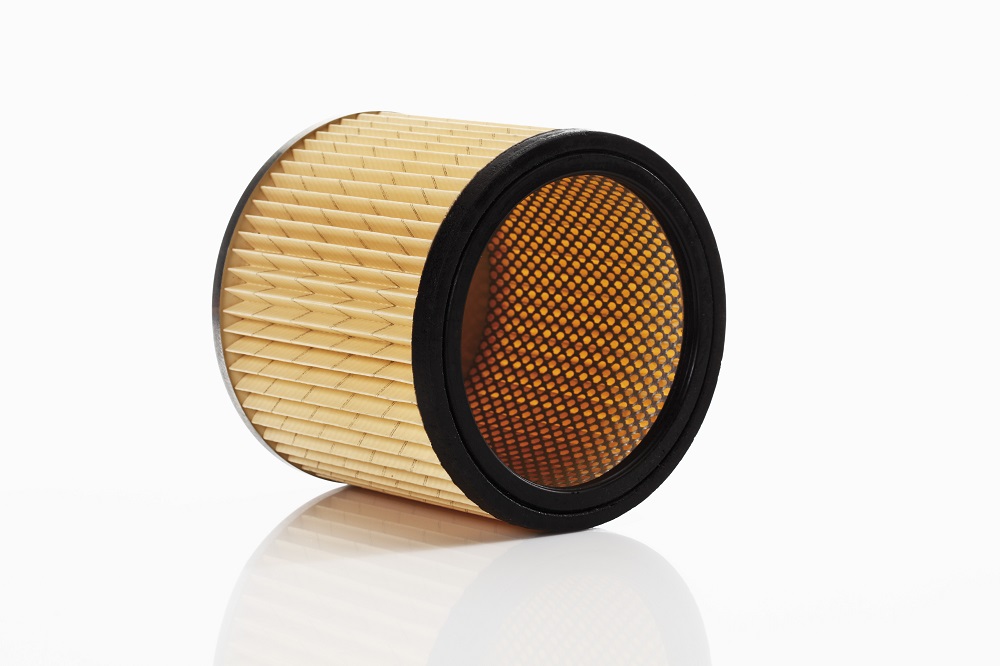

| Vacuum Filters |

The vacuum filtration is widely used in all varieties of food processing industries, chemical factories, and the pharmaceutical companies, for enhancing the productivity in these manufacturing units. There are different types of vacuum filters, based on the structural designs of these essential machinery parts. They are large-sized industrial vacuum cleaners; namely Precoat filter, Belt filter, Tray filter, Drum filter, Disc filter, Tilting Pan filter and Table filter. The filter is considered as the most important part of a vacuum cleaner, as it sucks even all the minute dust particles from the surfaces of a factory, ensuring absolute cleansing at this workplace. The filter is generally placed a few feet above the ground or below the vacuum pump for better suction, as per the layout design of the vacuum filter station.

Benefits of The Rapid Industrial Application of The Vacuum Filters

- These filters help the vacuum cleaners to operate continuously in the factories, where the production of debris is as constant as the actual factory production of the end products.

- The special mechanisms of the vacuum filters prevent the return of the sucked dust particles onto the cleaned spaces, by holding back all these minute particles within the vacuum cleaning machine. Mainly the fine ones that cannot be otherwise held back along with the larger particles inside the vacuum receivers at all without the installation of these filters.

- The working environment of a factory can remain much cleaner and healthier for the workers, due to the continuous use of these filters for vacuuming the entire production space.

- These filters are easily washable with water at normal room temperature, making the maintenance of the vacuum machine much simpler for the operators. Moreover, the cleaning of the filters enables the increased cleaning of the factory spaces in more frequent intervals, resulting in accurate cleansing.

|

| Vacuum Cleaner Filter |

- As all the machines of a factory are regularly cleaned by the vacuum cleaners, the productivity can be increased many times than the otherwise speed of production, thus boosting the commercial benefits of the company.

- It becomes more convenient for the operator to handle a vacuum cleaner that is fitted with an effective type of filter, because of the useful parameters with the suitable thickness of the filtration plate and its ability to wash and clean at any time.

- The uses of vacuum cleaners have been made more popular in the factories, due to the basic difference brought to the usual domestic cleaner and the installation of these various types of industrial vacuum filters.

- The filter station of a vacuum cleaner can be made of different types of materials and this variation is seen according to the requirements of the users and the budget of the companies in regard to the cleansing system.

Hence, the filters of industrial vacuum cleaners are highly advantageous for the machines, workers and also the company authorities, leading to the huge popularity of these filtration systems.

No comments:

Post a Comment